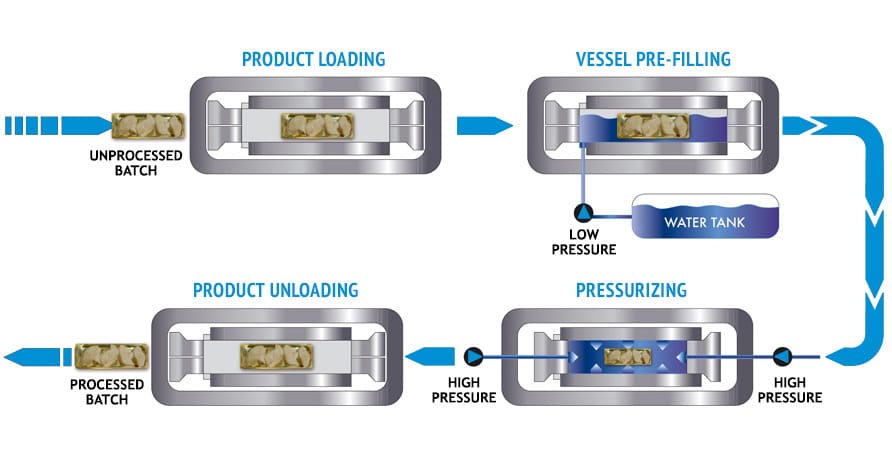

High pressure processing (HPP) has been essential for the development of the Global Avocado industry. The HPP process is a non-thermal food preservation method that uses water at room temperature (4-25 ° C) to generate pressure levels of up to 6,000 bar (87,000 psi / 600 MPa) on products already in their final packaging. That means close to 6 atmosphere pressure or 87,022.64 pounds per square inch of pressure.

For avocado-based products, High-Pressure Processing provides the delicate balance between quality, nutrition, safety and convenience, meeting the high expectations of consumers and avocado processors that demand a clean label, as well as meeting strict regulatory standards.

You can read the original A23L 3/015 (2006.01) HPP Patent here, invented by Adam Cornell (Australia)

Nutritional value and product safety are two of the most important factors influencing food consumer choices at the present time, as well as being of significant importance to toad producers and distributors.

In the food industry, one of the long term goals is to assure food safety and extend product shelf life while retaining the characteristics of fresh, preservative-free, and minimally processed foods.

Traditionally, heat-based methods are used to destroy harmful bacteria and reduce the numbers of spoilage organisms to extend shelf life of food products. Such methods are well known and are the subject of highly developed techniques.

However, consumer demand for fresher tasting and fresher textured foods is driving the development of new methods of making the energy-intensive process more environmentally friendly, further extending shelf life and producing a product with a taste as close to an untreated product as possible.

An advantage of HPP over heat pasteurisation and other thermal processing technologies is the even and instantaneous distribution of pressure energy throughout the product.

You can see and learn more about the Avocado Pulp HPP Process in the Hiperbaric Company Webinar (USA, Florida)

[ts_youtube url=”https://www.youtube.com/watch?v=zh2UoBkMinM”]

Because the High Pressure Process is applied to the dairy food in its final packaging, the product is not subject to post-processing contamination with spoiling or pathogenic microorganisms, resulting in a product with a longer shelf life than products that are heat pasteurised and subsequently packaged.

In high pressure processing (HPP), there are two key variables that define the treatment process. Every different food type requires testing to ascertain at what point the process has been effective in inactivating the target pathogens. The variables are: time spent under pressure; and the magnitude of pressure applied.

With typical HPP equipment, pressure can be applied up to about 6000 Bar. The time that a food item is placed under this level of pressure must be consistent with commercial food production process requirements and result in elimination or inactivation of a sufficient proportion of the target micro-organisms while maintaining the quality, texture and taste properties of the food.

Read more about the HPP Process patent here:

HPP Process Patent AU2017101178A4